Prevention of Oligomer trouble during polyester dyeing :「TEXPORT PEEL」

Oligomer problem during polyester dyeing is recognized as an issue never be solved in dyeing industry.

NICCA Chemical has created the oligomer removing agent "TEXPORT PEEL" as the world first product, over more than 4 years research and development.

TEXPORT PEEL is applicable not only for oligomer elimination but also several other usage by combining other chemicals and in different processes. Let us take a look into this big potential product to share how this successfully solve the problems.

Long way to come across the solution

STEP 01 Back ground

Oligomer causes serious problems

Oligomer is a by-product being generated during polyester elaboration, and it always stays in the polyester fiber. During the polyester dyeing, polyester fiber swells at high temperature and the oligomer comes out on its surface. That oligomer will not disolve in the water and it gets stained on the fabric, yarn surface and deep inside of dyeing machine.

If on the yarn, it becomes powdery looking and cause the stain and yarn breakage, and if on the fabric, it causes white powder and shady spots and badly deteriorates the product quality. In the case the oligomer stains get accumulated inside of dyeing machine, it stains the dyeing goods which causing lower productivity due to reduction of heat exchanger effciency.

This is how the oligomer gives bad impact on the productivity and product quality.

STEP 02 Discovery of the factors

Conventional remedy and issues

Following methods were the conventional option to cope with oligomers in the past.

- Stop the oligomers generation

- Prevent the generated oligomers from attaching to fibers

Alkali polyester dyeing is a one of good solutions, but those dyestuff is not much avaliable in the market, shade is limited and quality varies.

Oligomer dispersing agent can disperse the oligomer and prevent the redeposition to fiber, but it is not forcibly removing the oligomer from fabric or fiber. This is far from the perfect solution.

Further more, in recent years, high speed spinned yarn or recycled polyester yarn are increasing in the market which is also cauing further generation of oligomer on the surface, and those facts are making this problem more seriously.

STEP 03 Product Development

Mechanism of new idea

NICCA Chemical approached this oligomer problem from a totaly different angle.

It is the measurement to "Forcibly remove the oligomer which attached on the fiber".

The concept is ”PEEL off the oligomer", and it named the product "TEXPORT PEEL".

STEP 04 Reaching to the Solution

Drastically removed the oligomer which remains on the fiber! Powdery stains gone!

Adding "TEXPORT PEEL" during the polyester dyeing with disperse dyestuff dramatically reduced the residual oligomer on the fiber.

We also confirmed that the oligmer amount in the drained water became 7.5 times bigger than without TEXPORT PEEL which verify the oligomer removing property.

Application

Tested fabric:Polyester woven Dyeing condition:130°C×30min(Jet dye machine)

Test result

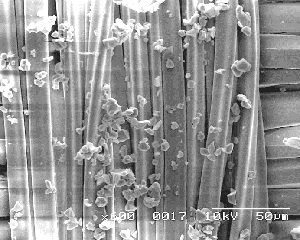

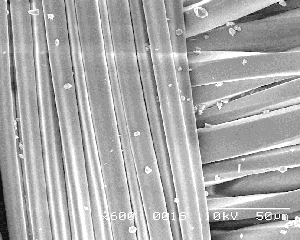

1. Oligomer observation on the fiber surface(SEM)

Conventional Process

With “TEXPORT PEEL”

The effect of oligomer removal is obvious

2. Oligomer observation by drained water

With out “TEXPORT PEEL”

Oligomer quantity in the solution

15mg

With “TEXPORT PEEL”(3%o.w.f.)

Oligomer quantity in the solution

113mg

"TEXPORT PEEL" is not only for removing oligomer which attached on the fiber.

It also contributes to prevention of stains inside of dye machine which leading less frequent machine cleanings and increasing productivity

R&D Person in Charge

NICCA CHEMICAL (HQ)

R&D Dept.

Masaaki Hosoda

Solve the Never ending problem in polyester dyeing!

Against the difficult challenge in the polyester dyeing industry which every body says "Impossible" to solve, we spent 2 years for elaboration and development of application, 1.5 years for engineering in bulk production, and have completed the development of "TEXPORT PEEL".

Polyester fiber is widely utilized in our daily life. We hope "TEXPORT PEEL" will add values in our customers' procutivity and quality improvement.

Back to the list