Quality improvement & process rationalization for Cotton knit scouring/bleaching:「SUMORL BH series」

In the scouring and bleaching processing of cotton knit, quality improvement and cost reduction by process rationalization are considered to be very difficult challenge. Especially shorter process or low temperature are almost impossible if you want to maintain the high quality such as whiteness of the fabric.

NICCA Chemical has successfully developed a scouring agent "SUNMORL BH-series" which realizes both requirements.

Let us take a look at the benefit which brought by this product to our customers.

Long way to come across the solution

STEP 01 Back ground

Fierce competitions in cotton knit factories

For scouring and bleaching process for cotton and cellulosic fiber, it is required to have even more whiteness or improve the quality on difficult materials such as fine count yarn. We have to have the technical performance to support higher value added goods to meet the final goods suppliers' requirement.

Batch process of cotton scouring/bleaching requires high temperature and long time which consume huge amount of steam and long time.

This repeating process for every batch is the cause of big production costs.

This is the challenge for cotton processing factory to improve quality and productivity in a long-term sustainable operation.

STEP 02 Discovery of the factors

Conventional remedy and hanging issues

This is conventional process of quality improvement and process rationalization;

- High whiteness:

Stronger condition in Temp., Time and Recipes(by Alkali and Hydrogen Peroxide dosge)

- Process rationalization:

Shortening process time or lowering process temp.

Stronger conditions could increase the whiteness, however, it causes lowering the fabric strength and water absorbency, hardening the handfeel.

And process rationalization could not maintain the conventional whiteness level and quality. It was far from the solution.

STEP 03 Product Development

Activation of Hydrogen Peroxide

How we can get higher whiteness with milder scouring/bleaching condition?

NICCA Chemical has reached to one integrant which activates the hydrogen peroxide much more effectively.

That ingredient made it happen to obtain higher whiteness even with lower temp. and shorter process of scouring/bleaching condition, then "SUNMORL BH-series has been brought out in the market.

STEP 04 Reaching to the Solution

Contribute to reduction of Production cost with better quality!

Just switching the scouring agents from conventional type to "SUNMORL BH-series" will realize higher whiteness.

And against the delicate materials which becomes weaker in strength and harder in handfeel under strong bleaching condition, you will use "SUNMORL BH-series" and get higher whitenss even under milder condition.

Application

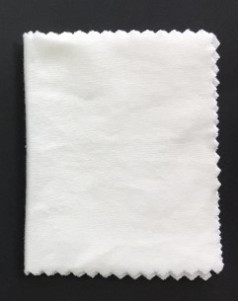

Tested fabric:Cotton knit

Treatment condition:BR=1:12 Ramp rate 3℃/min x℃×y min → cold rinse 5min → Dry at 100℃

Test result

1. Whiteness

Grey

Conventional

BH-series

2. Rationalization (Shorter process/Low temp.)

R&D Person in Charge

NICCA China

R&D Dept.

Shang Yaozeng

Make it possible in the challenge of improving quality and cost reduction at the same time!

We have developed the "SUNMORL BH-series" by focusing on the mechanism of scouring/bleaching on Cellulosic fiber.

Cellulosic fiber such as cotton is required to have not only high whitness but also good handfeel and water absorbency.

I believe that "SUNMORL BH-seriese" will contribute to higher productivity in the factory and higher quality which bring new value to the market.

Back to the list