Rapid growth in demand!

Water Repellent and Antiviral processing required for Medical field.

A new type of coronavirus infection (COVID-19) that spreads worldwide. In the medical field involved in the transportation and treatment of patients, they continue to fight viruses as strict infection-control measures have been taken. A variety of Textile products have been developed to enable medical professionals to more safely access patients. Medical gowns, such as isolation gowns, are also one of the protection devices used to combat infectious diseases. These protective equipment are strengthening production capacity in each country, and at the same time, demand for Water Repellent and Antiviral processing is increasing.

In this issue, we will introduce Medical gowns and our Water Repellent and Antiviral agents.

Long way to come across the solution

STEP 01 Back ground

Protective equipment for protecting persons from infectious diseases

Protective equipment that protects medical professionals from infectious diseases is called PPE (Personal Protective Equipment). The use of PPE is an effective way to block the route of infection in the control of infectious diseases, and gowns worn by medical field are also included in PPE. Infectious diseases can be transmitted by a variety of routes, including splash infection, airborne infection, and contact infection, and the optimal use of protective equipment leads to the protection of medical professionals.

STEP 02 Discovery of the factors

Deficiency of protective equipment (PPE) caused by an infectious explosion

Medical gowns are usually worn by nurses to prevent splashes in emergency situations and on wards, and by visitors to ICUs and NICU patients. However, demand for PPE has increased dramatically due to the outbreak of infection with new coronavirus worldwide! Production cannot catch up even with full operation by existing manufacturers, and we are increasing production capacity in each country, such as by requesting manufacturers of apparel clothing to make capital investments in the production line of medical gowns. Medical gowns are provided with various grades of finishing depending on the intended use. Water Repellent to prevent splash infections and Antiviral effect to reduce the number of viruses on textile are finishing required for protective clothing when contacted with infected patients.

STEP 03 Product Development

Water Repellent chemicals and Antiviral agents

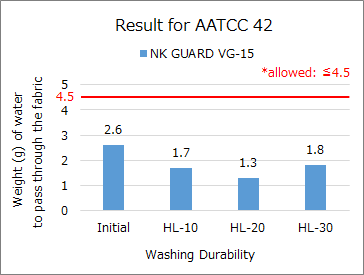

For many years, NICCA Chemical has been providing NK GUARD, KF GUARD, and NEOSEED Water Repellent chemicals for outdoor wear and other materials that require high water repellency and durability, as well as surgical clothing and other areas that require water repellency and water pressure resistance to protect against blood. Water Repellent chemicals are also used as Soil Releasing agents to prevent stain from adhering to textile.

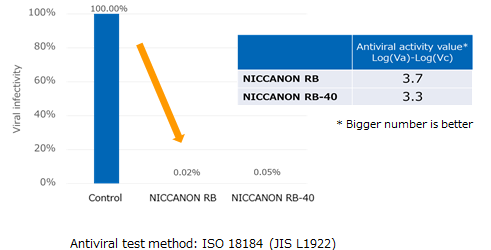

In addition, we have confirmed the antiviral effectiveness of fabrics newly processed with Antibacterial agents "NICCANON RB" and "NICCANON RB-40". Antibacterial and Antiviral finishing are expected to be applied to medical gowns, masks, filters, mops, curtains, clothing, and various other textile products.

STEP 04 Reaching to the Solution

Aiming for a safer medical environment

NICCA CHEMICAL wants to contribute Water Repellent chemicals and Antiviral agents to provide safer work environments for medical professionals who fight viruses at the forefront. If you are considering of developing and producing textile products with Water Repellent finish and Antiviral finish, please feel free to contact us.

Test result

Tested fabric: CVC knitted fabric

Processing method: Pad → Dry-Cure (180℃×3min.)

Dosage: 80g/L Pick-up: 80%

Test result

Tested fabric: T/C knitted fabric

Processing method: Pad → Dry (130℃×2min.)

Dosage: 50g/L Pick-up: 80%

※ Performance differs depending on the material, cloth weight, processing method, and the presence or absence of coating. Please check the material in advance.

R&D Person in Charge

NICCA CHEMICAL (HQ)

R&D Dept.

Yoshiki Tsuge

Water Repellency to prevent water permeation such as splashes, Soil Resistance to prevent water and oil stains from adhering, and Antiviral properties to reduce the number of viruses adhering to textiles...

Both of these are considered to be finishing that play key roles in a variety of environments, including the medical field that fights against infectious diseases. We hope that our functional chemicals will be processed into all kinds of textile products, which will contribute to the healthy and safe lives of people as much as possible.

Back to the list