Go for Zero-waste in Fashion Textile -Polyester upcycle technology 『NEOCHROMATO』 process to be launched by joint development with Elephantech

We are pleased to announce that it has developed a dye discharging technology from printed or dyed polyester fabric, jointly with Elephantech Inc. (Headquartered in Tokyo Chuo-ku, CEO Nobuya Shimizu, herein after Elephantec), which enables to easily remove the dyes without using water and re-dye or put new printing again on the fabric to revive the value with different design.

In recent years, due to the increase in people's awareness of sustainability, the mass disposal of apparel and textile materials has become a social problem. There is a report that the total supply of clothing in Japan is 819,000 tons (in 2020), while the total amount of waste is 510,000 tons*, and it is our mission to effectively use global resources and reduce environmental impact through upcycling of fashion and sports apparel materials.

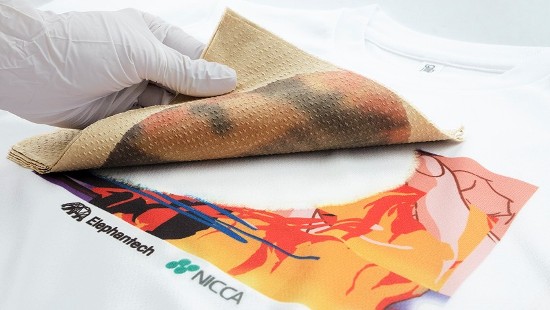

In collaboration with Elephantech, we have developed an innovative technology that can discharge only dyes from polyester fabrics dyed with disperse dyes almost completely in a matter of minutes, by a high-safety chemical product, without using large-scale equipment. Discharged areas can be dyed and printed, and you can enjoy new designs as many times as you like with this technology (Please see the picture below).

There will be a wide range of scenes using this technology, whenever we want to change the design of everyday T-shirts according to the season and mood, also for the seasonal redesign of sports uniforms, the redesign of polyester signage which is no longer needed and for the discharging of polyester fabrics to make it a raw material for material recycling, where we expect to make a significant contribution to Zero waste in fashion textile and the circular economy.

We would like to verify the potential of this technology by communicating with apparel brands.

*Sourced: 2021 The Japan Research Institute, Limited

Processing Method Video (Youtube)

https://youtu.be/GUcVjU_L-AM

Related webpage “Neochromato process”

https://info.elephantech.co.jp/en/neochromato

Comments from the development team

ELEPHANTECH:

The development of this technology came about following a conversation we had with the artist Ms. Aguri Sagimori in which we realized that there could be a huge amount of clothing waste from the fashion industry should the Tokyo 2020 Summer Olympics be postponed and rebranded as TOKYO 2021, and that we somehow needed to develop a technology to upcycle it all. As it happened, the event was postponed but thankfully kept its TOKYO 2020 naming, avoiding the mass waste we feared. However, we also came the see that the fundamental issue was how many pieces of clothing are only worn few times before being disposed of anyway, and so we continued our trial-and-error process along with many stakeholders in order to perfect the technology. As a result, we ended up with a magical technology that can erase and reprint prints over and over again.

We hope that this Neochromato process technology will be used by many and contribute in bringing an era where we can enjoy sustainable fashion.

NICCA CHEMICAL:

We have started our spontaneous, in-house open lab activity called “MO-SO (delusion) Meeting” after being inspired by Elephantech Vice President Masaaki Sugimoto’s lecture at our NICCA Innovation Center. The development of this technology first began when Masaaki Sugimoto and Aguri Sagimori showed interest in the result of an experiment by MO-SO Meeting team which could involved blurring characters and patterns to make them indistinguishable. We then obtained the cooperation of Japan Polymark Co., Ltd. when considering practical applications of the technology. We named the technology "Neochromato" process after how the dispersed dye would be mysteriously extracted from polyester and be transferred as if in paper chromatography. We hope to convey to the world our desire to reduce textile waste through upcycling and to use as little water as possible throughout the process.

Back to the list