NEOSEED series is a PFC-free durable water repellent. Despite being an eco-friendly product, it has a water repellent function comparable to that of conventional fluorine-based water repellents.

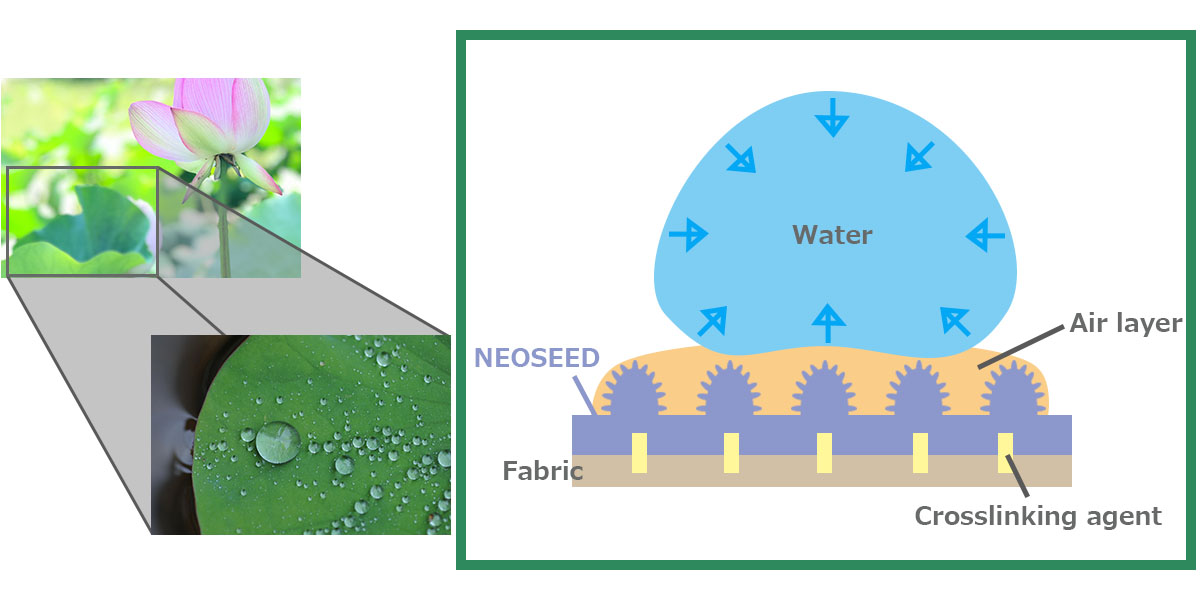

Mechanism of NEOSEED

Though the leaf of the lotus plant may seem smooth at a glance, you will find the surface is covered with microscopic projections.

Air becomes trapped in the spaces between the projections, forming an air layer that functions to enhance the surface tension of water coming into contact with it. Like magic, the water forms into round droplets that roll smoothly off the leaf. NEOSEED series reproduces this principle on fabric.

Product Lineup

We have products and processing recipes that meet your needs.

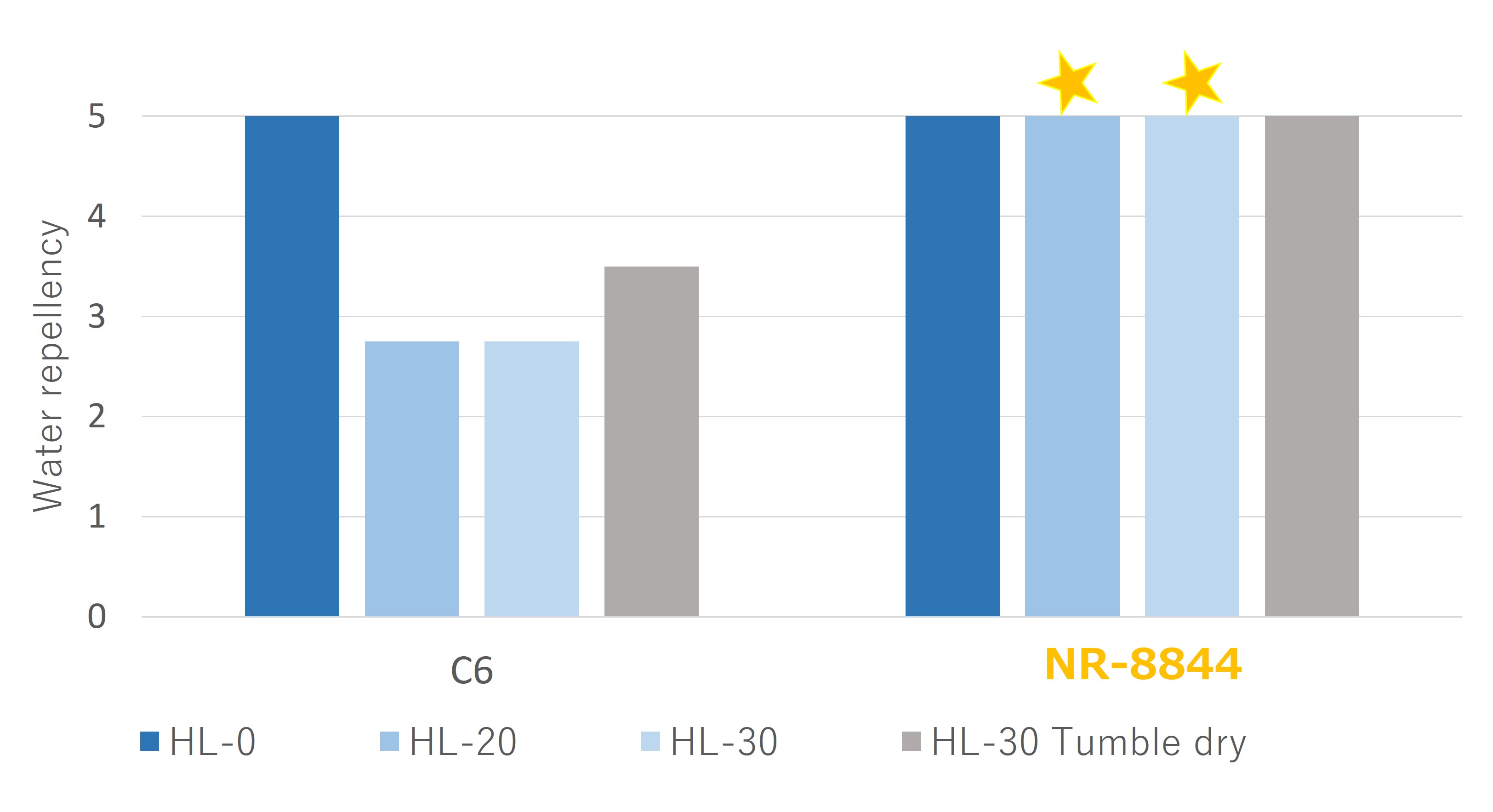

NEOSEED NR-8844

Demonstrates excellent durable water repellency that exceeds C6 fluorine-based water repellent in "natural drying".

It features slip resistance and a soft texture. Ideal for processing outdoor wear that moves actively outdoors.

Evaluation results of DWR

Fabric:Polyester taffeta (fabric)

Recipe:Water Repellent + Crosslinking agent

Treatment:Pad → Dry 130℃ → Cure 170℃

Laundry:JIS L 1930 : 2014 C4M method

Evaluation:JIS L 1092 : 2009

More

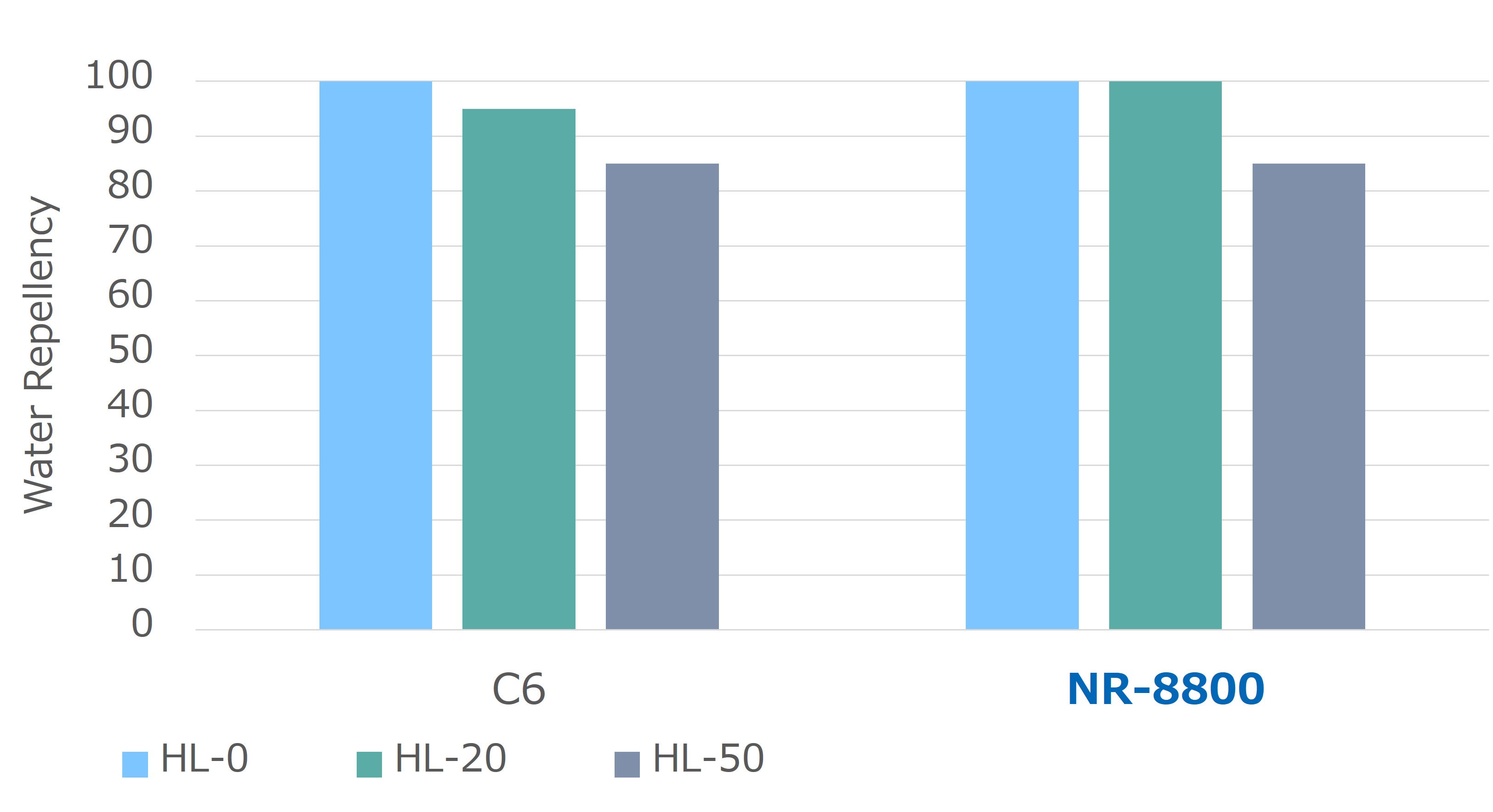

NEOSEED NR-8800

Imparts both a soft hand and excellent durable water repellency.

Ideal for processing Down coats, Windbreakers, Sleeping bags (single layer) that require a soft hand feel.

Evaluation results of DWR

Fabric:100% Polyester (woven fabric)

Recipe:Water Repellent 6%soln. + Crosslinking agent 1%soln.

Treatment:Pad → Dry 120℃ → Cure 170℃

Laundry:AATCC135

Evaluation:AATCC 22-2010

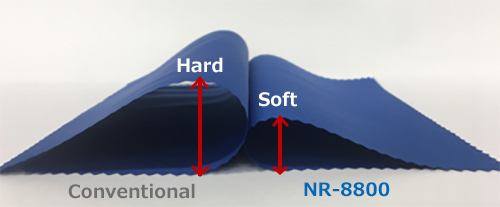

Achieve softness

Fabric:100% Polyester (woven fabric)

Recipe:Water Repellent 6%soln. + Crosslinking agent 1%soln.

Treatment:Pad → Dry 130℃ → Cure 170℃

Evaluation:Visual evaluation of the flexibility of the folded fabric

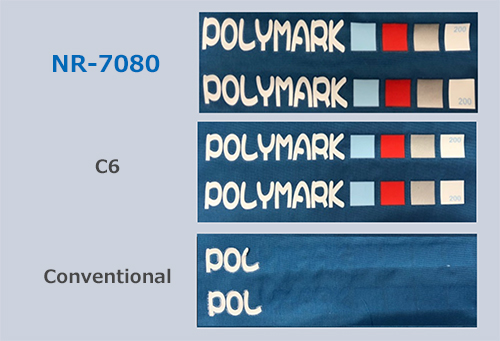

NEOSEED NR-1060

Although silicone-based water repellent has both a soft hand and excellent peeling strength.

It also shows excellent adhesion to transfer printing of brand logos.

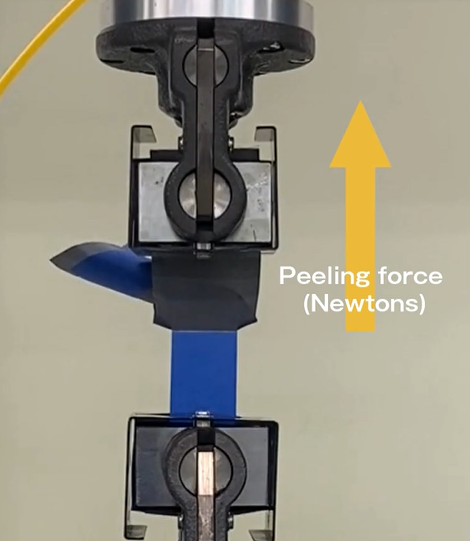

Peeling strength tests

Fabric: 100% Polyester (woven), 100% Nylon (woven)

Recipe: NR-1060 4% soln. or C6 Water Repellent 6% soln. + Crosslinking Agent 1% soln. + Penetrant 1% soln.

Treatment: Pad → Dry 120℃ → Cure 170℃

Evaluation: Peeling strength

JIS L 1086:2013 Testing methods for fusible interlining fabrics and laminated fabrics reference

More

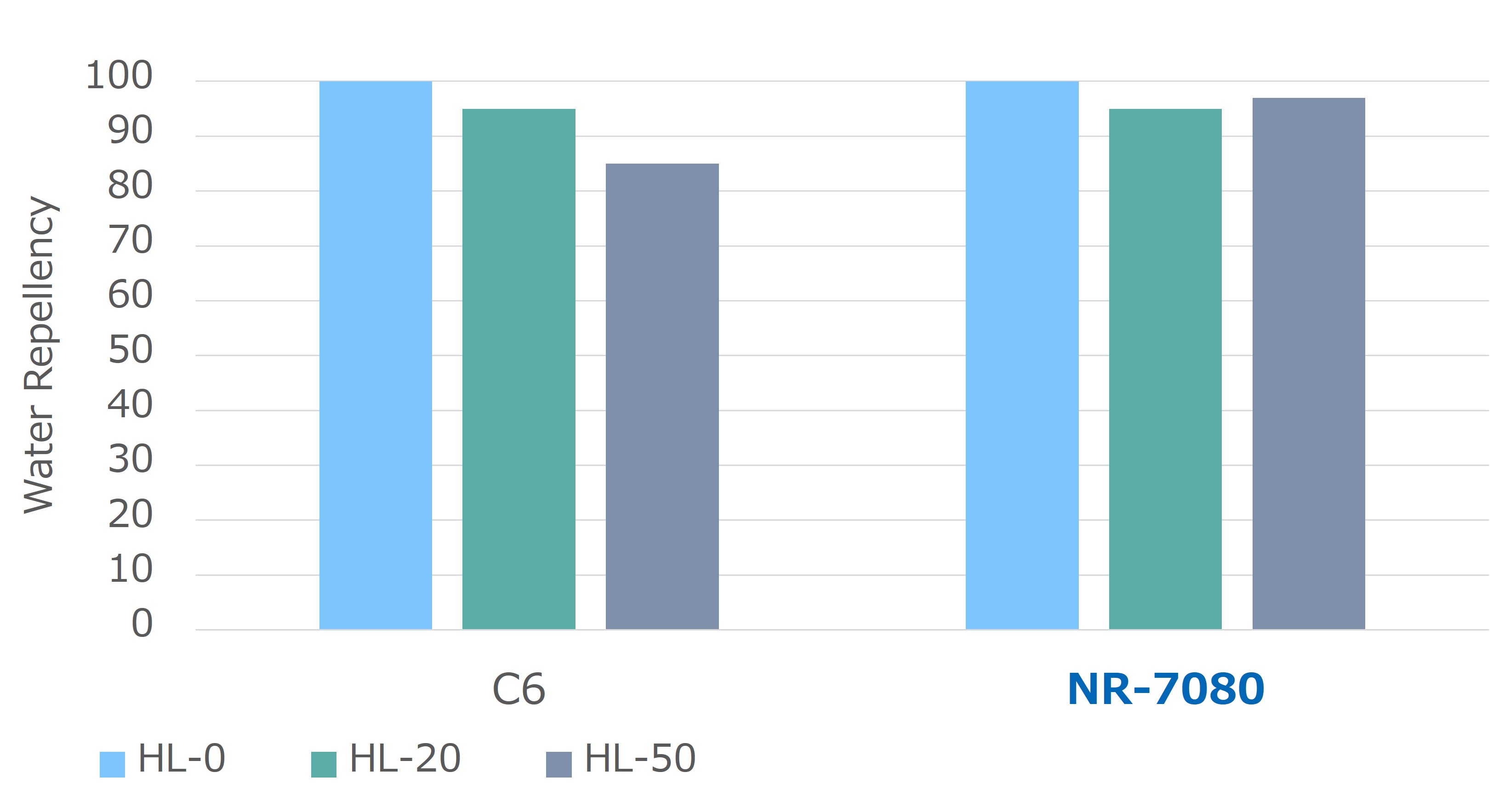

NEOSEED NR-7080

Provides excellent peel strength and water repellency.

Ideal for processing outdoor wear and uniforms.

Evaluation results of DWR

Fabric:100% Polyester (woven fabric)

Recipe:Water Repellent 6%soln. + Crosslinking agent 1%soln.

Treatment:Pad → Dry 120℃ → Cure 170℃

Laundry:AATCC135

Evaluation:AATCC 22-2010

Excellent Peel strength

Gives peeling strength equivalent to C6 type water repellent.

Suitable for coating and laminating.

Fabric:100% Nylon (woven fabric)

Recipe:Water Repellent 6%soln. + Crosslinking agent 1%soln.

Treatment:Pad → Dry 120℃ → Cure 170℃

Evaluation:

JAM method (Sticker #240 HOT type 175℃×10sec. Pressure 2kgf/㎡) Gummed tape test

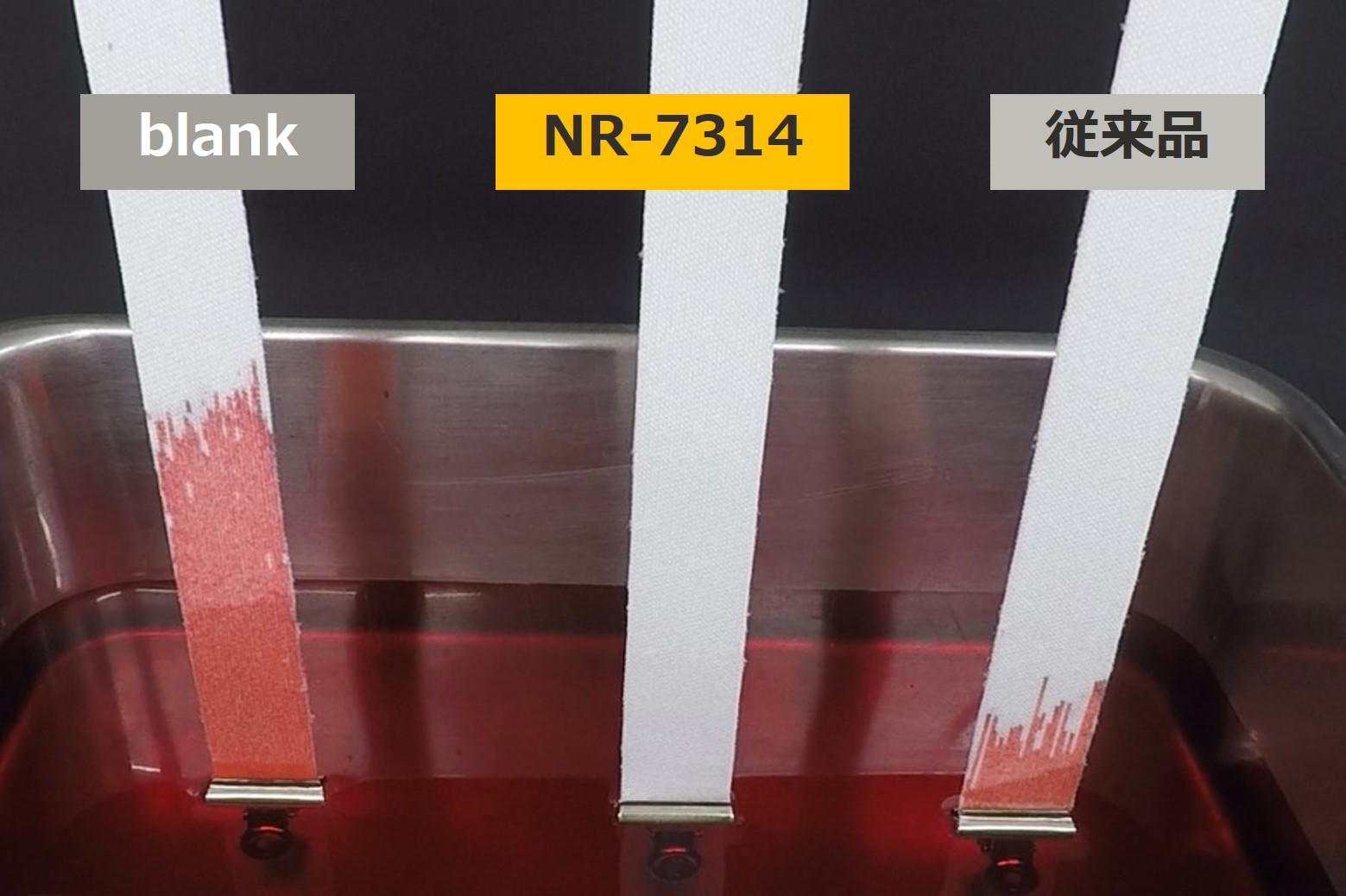

NEOSEED NR-7314

It features excellent anti-wicking properties even when wet.

It is ideal for products where soaking is a concern, such as shoes or bags.

Wick rise test (After 2 hours)

NR-7314 does not absorb water at all.

Fabric: 100% Polyester (knit)

Recipe: Water Repellent + Crosslinking agent

Treatment: Pad → Dry130℃ → Cure170℃

Test method: The absorption of water from the lower art of the test fabric, measures for 2 hours.

More

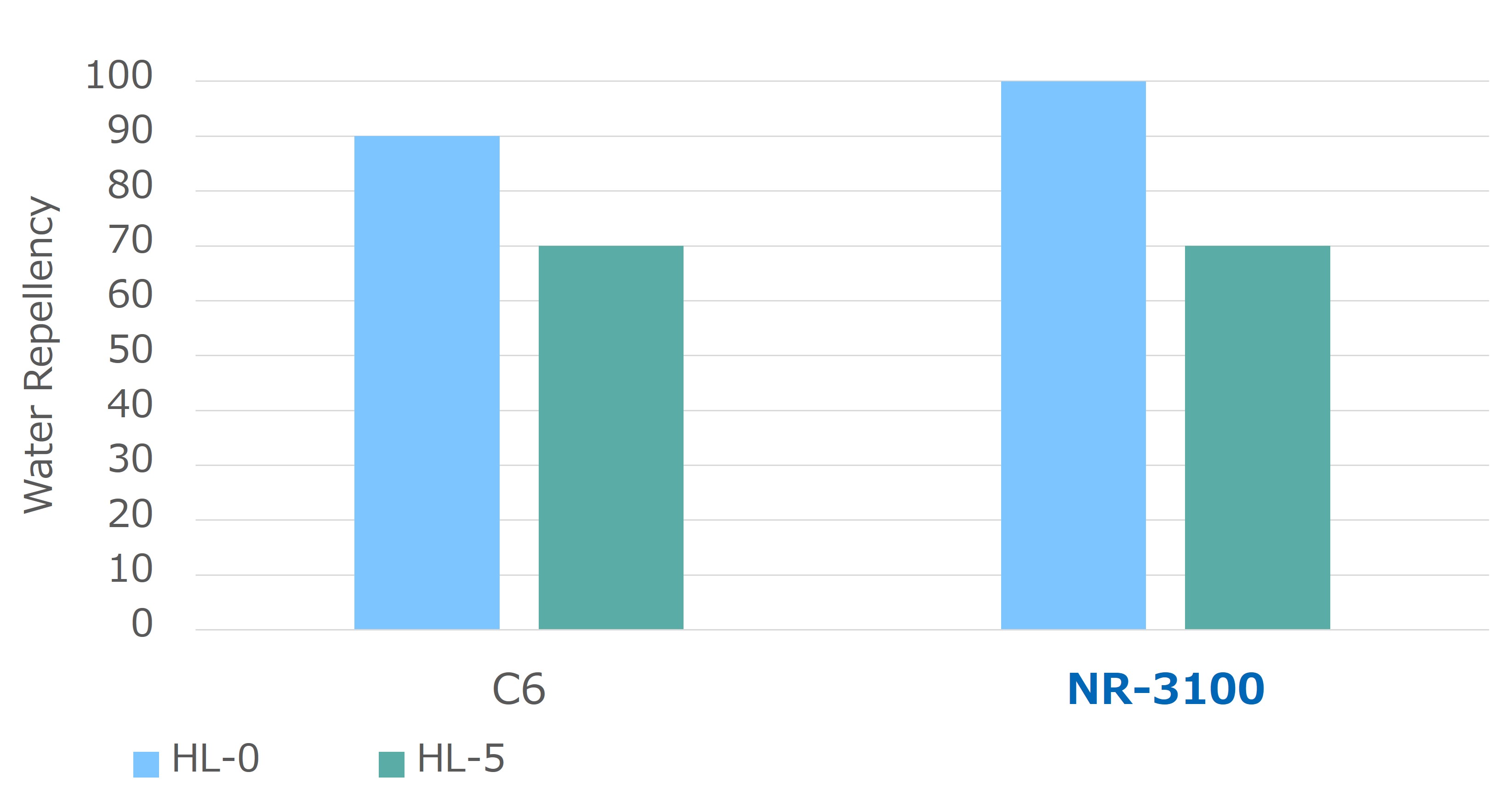

NEOSEED NR-3100

Provides excellent water repellency to cellulose fabrics and cellulose blends, and also imparts dry cleaning resistance.

Ideal for processing apparel wear and denim.

Evaluation results of DWR

Fabric:100% Cotton (woven fabric)

Recipe:Water Repellent 10%soln. + Crosslinking agent 1%soln.

Treatment:Pad → Dry 120℃ → Cure 160℃

Laundry:AATCC135

Evaluation:AATCC 22-2010

More

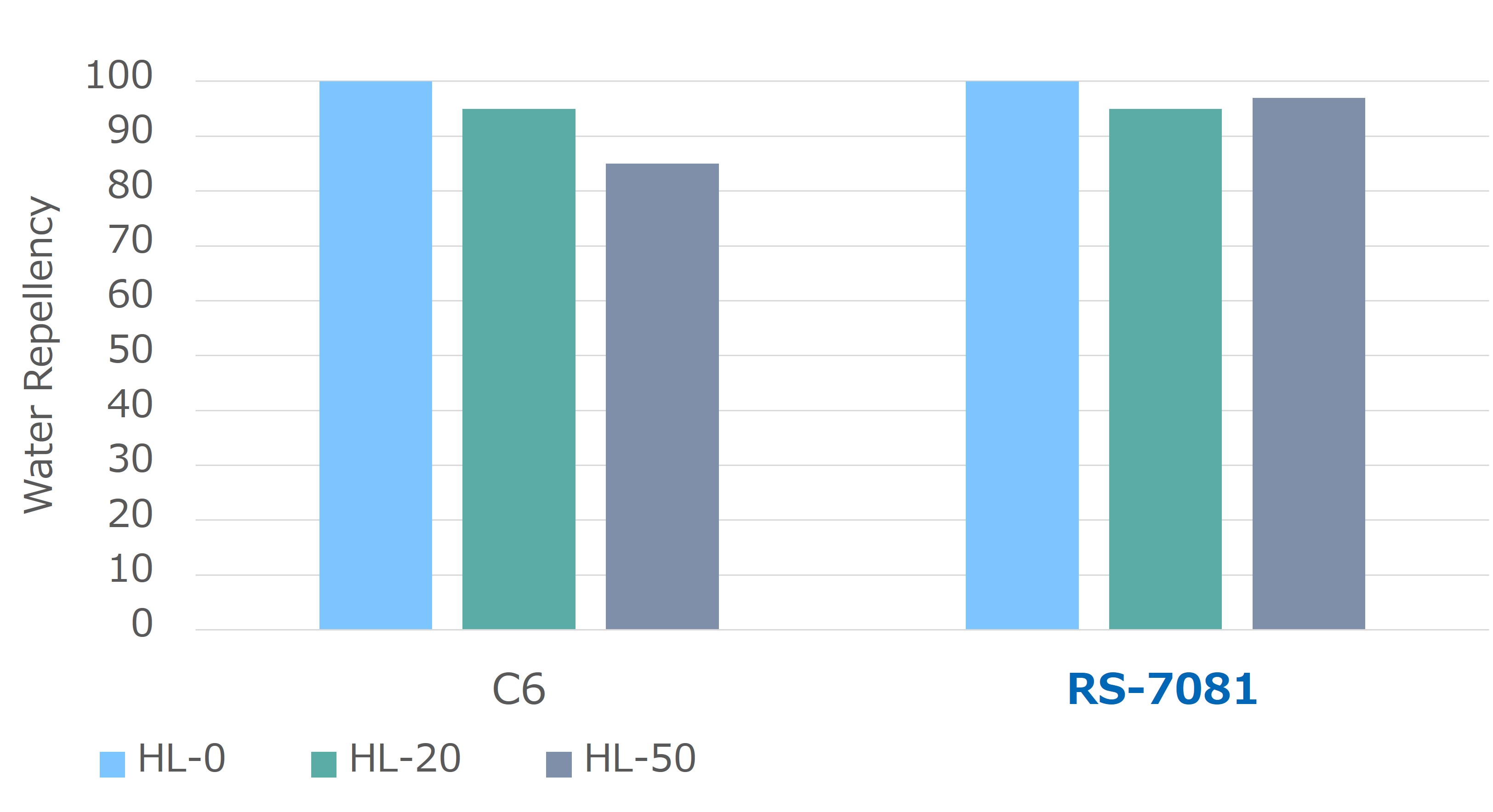

NEOSEED RS series

Contains sustainable palm oil as a raw material to increase the added value of our products.

Evaluation results of DWR

Fabric:100% Polyester (woven fabric)

Recipe:Water Repellent 6%soln. + Crosslinking agent 1%soln.

Treatment:Pad → Dry 120℃ → Cure 170℃

Laundry:AATCC135

Evaluation:AATCC 22-2010

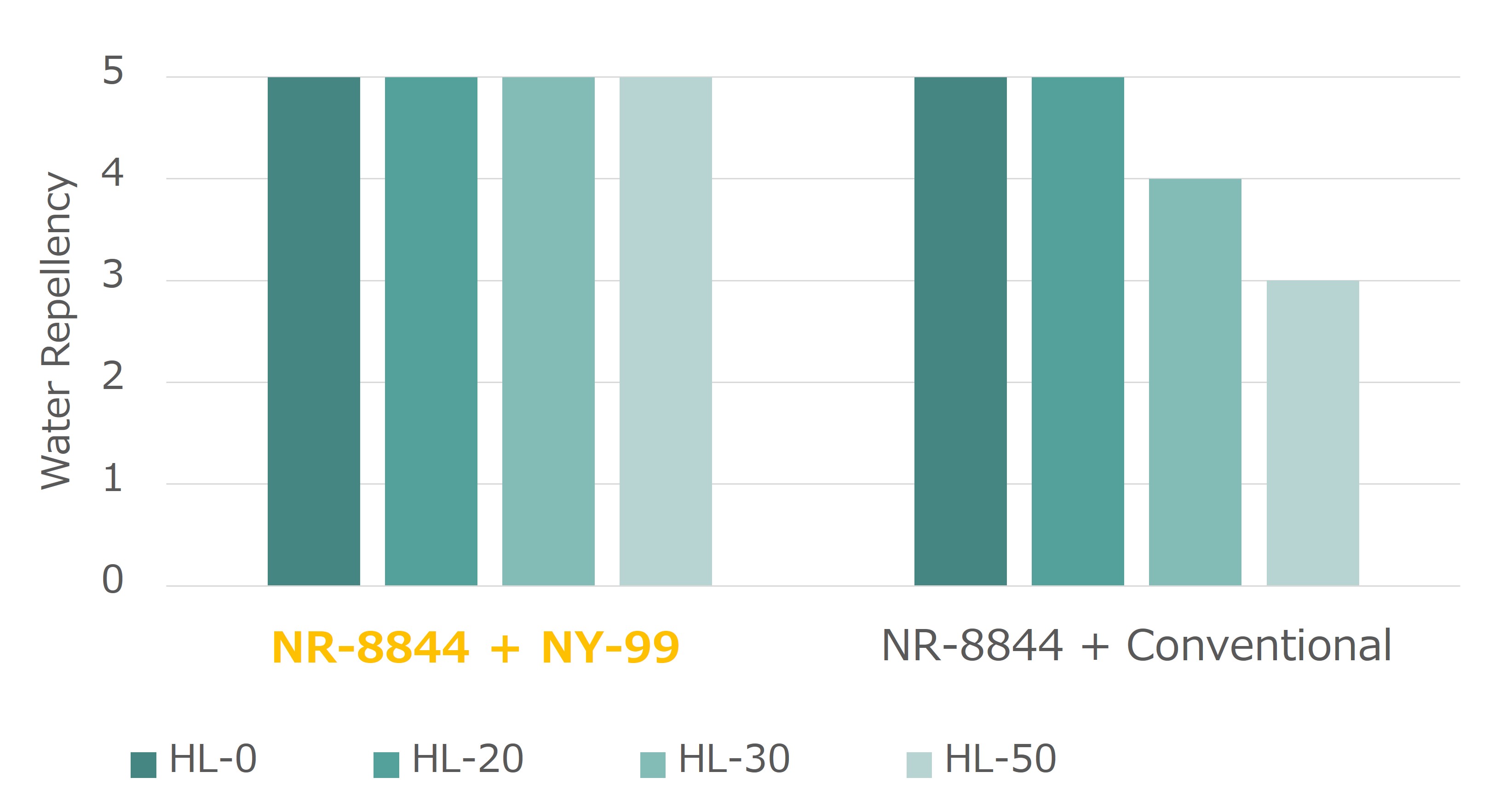

NK ASSIST NY-99

NK ASSIST NY-99 is a non-yellowing type crosslinking agent.

It exhibits excellent durable water repellency when used in combination with either acrylic water repellent or silicone water repellent.

Evaluation results of DWR

Fabric: Polyester taffeta (woven fabric)

Recipe: NEOSEED NR-8844 6% soln. + Crosslinking agent 1% soln.

Treatment: Pad → Dry 130℃ → Cure 170℃

Laundry: JIS L 1930: 2014 C4M method

Evaluation: JIS L 1092: 2009

More